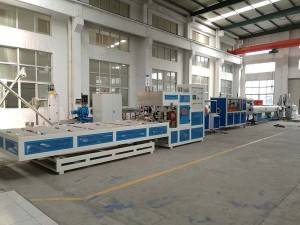

PVC Pipe Production Line

Inquiry NowDetailed Product Description

| model | FGE63 | FGE110 | FGE-250 | FGE315 | FGE630 | FGE800 |

| pipe diameter | 20-63mm | 20-110mm | 75-250mm | 110-315mm | 315-630mm | 500-800mm |

| extruder model | SJ65 | SJ75 | SJ90 | SJ90 | SJ120 | SJ120+SJ90 |

| motor power | 37kw | 55kw | 90kw | 160kw | 280kw | 280KW+160KW |

| extrusion capacity | 100kg/h | 150kg | 220kg | 400kg | 700kg | 1000kg |

large diameter PVC pipe extrusion line

This line is mainly used for producing UPVC pipes with large diameters and different pipe wall thickness in the aspects such as the agricultural and constructional plumbing, cable layietc. The max diameter of pipe could be 1200mm.

The process flow of this line as blow

PVC powder + additive --- mixing---material feeder---twin screw extruder---mould and calibrator---vacuum forming machine---spraying cooling machine---haul-off machine---cutting machine---discharge rack or pipe belling machine.

The screw of extruder has advanced design, which provide powerful safeguard for the PVC plasticization, and the Siemens PLC control system make more convinient operation. The degassing system will ensure the quality of final PVC pipes.

The tank body of vacuum calibration and cooling units adopt stainless 304# steel, multi-sections vacuum system ensures the stable sizing and cooling for pipes; Special cooling system improves the cooling efficiency; Auto water temperature control system make the machine more intelligent.

For different pipe size, the haul-off machine will adopt two caterpillars, three caterpillars, four caterpillars, six caterpillars are designed for different requirements. Pedrail clamping uses mechanical and pneumatic combining system, which is more reliable in performance

Cutting system adopts no-dust cutter or planetary cutting means; There is dust-collecting system ensures clean working environment.

Technical data

| model | FGP160 | FGP250 | FGP315 | FGP630 | FGP800 |

| pipe size | 50~160mm | 75~250mm | 110~315mm | 315~630mm | 500~800mm |

| extruder | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ92/188 | SJZ92/188 |

| motor power | 37kw | 55kw | 90kw | 110kw | 132kw |

| output | 250kg | 350kg | 550kg | 600kg | 700kg |

Products Recommended

More +-

HDPE pipe extrusion line

It is widely used in producing HDPE water supply pipes, gas supply pipes. It can make HDPE pipes with diameter from 16mm to 800mm. With many years of plastic machinery development and design experience, this HDPE pipe extrusion line has the unique structure, the design is novel, the equipment entire line layout is reasonable, the control performance is reliable. By different requirement, this HDPE pipe line could be designed as multiply-layer pipe extrusion line.

Learn more -

Conical twin screw extruder

SJSZ series conical twin screw extruder is mainly composed of barrel screw, gear transmission system, quantitative feeding, vacuum exhaust, heating, cooling and electrical control components Etc. The conical twin screw extruder is suitable for producing PVC products from mixed powder.

It is special equipment for PVC powder or WPC powder extrusion. It has advantages of good compounding, large output, stable running, long service life. With different mould and downstream equipment, it can produce PVC pipes, PVC ceilings, PVC window profiles, PVC sheet, WPC decking, PVC granules and so on.

Different quantities of screws, double screw extruder have two screws, sigle screw extruder only have one screw, They are used for different materials, double screw extruder usually used for hard PVC, single screw used for PP/PE. Double screw extruder can produce PVC pipes, profiles and PVC granules. And single extruder can produce PP/PE pipes and granules.

Learn more -

12-575mm6.5mm thick PE pipe production line

It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it can also produce mufti-layer PP-R pipes, PP-R glass fiber pipes, PE-RT and EVOH pipes. With years of experience for plastic pipe extrusion, we also developed high speed PP-R/PE pipe extrusion line, and the max production speed could be 35m/min (base on 20mm pipes).

Learn more -

Automatic pipe belling machine

1.this series can be processed Φ16-1000mm any pipe flaring

2.with automatic delivery tube.flip tube.flaring function

3.with heating.cooling.timing.automatic.manual function

4.the modular design of the components

5.small size.low noise

6.the use of vacuum adsorption.flaring a clear profile.size assurance

7.power (compared with similar products.power-saving 50%)

8.can be customized according to user requirements special specifications

Learn more -

Automatic Winding Machine For Plastic Pipe Profile

It is mainly used for winding PE pipe, alumium pipe, corrugated pipe, and other some pipe or profiles. This plastic tube coiler is highly automatic, and usually work with whole production line.

The plate is controlled by gas; winding adopt torque motor; with special equipment to arrange the pipe, this plastic tube coiler can wind pipe well, and work much stable.

The main model for this plastic tube coiler: 16-40mm single/double plate automatic plastic tube coiler, 16-63mm single/double plate automatic plastic tube coiler , 63-110mm single plate automatic plastic tube coiler.

Learn more -

PVC granulating line

This line is widely used to in PVC granules and CPVC granules production. With proper screw, it can produce soft PVC granules for PVC cable, PVC soft hose, rigid PVC granules for PVC pipe, pipe fittings, CPVC granules.

The process flow of this line as blow: PVC powder + additive — mixing—material feeder— conic twin screw extruder— die — pelletizer — air cooling system — vibrator

This extruder of PVC granulating line adopt special conic twin screw extruder and the degassing system and screw temperature control system will ensure the material plasticization; The pelletizer is well blanced to match the extrusion die face; The air blower will blowing the granules into silo immedately after granules fall down.

Learn more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur