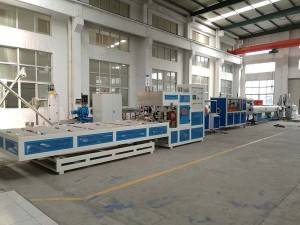

Plastic recycling pelletizing line

Inquiry NowHDPE pipe extrusion line

This line is mainly used to make granules from waste plastic material, such as PP, PE, PS, ABS, PA flakes, PP/PE films scraps. For different material, this pelletizing line could be designed as single stage extrusion and double stage extrusion. The pelletizing system could be die-face pelletizing and noodle-cut pelletizing.

This plastic granulating line adopt automatic temperature control and stable performance. The bi-metal screw and barrel is available and the special alloy giving it strength and long service life. It is more economic in electric power source and also water. Large output, long service life and low noise

Technical parameter

|

Model |

Extruder |

Screw Diameter |

L/D |

Capacity (kg/hour) |

| SJ-85 | SJ85/33 | 85mm | 33 | 100-150kg/hour |

| SJ-100 | SJ100/33 | 100mm | 33 | 200kg/hour |

| SJ-120 | SJ120/33 | 120mm | 33 | 300kg/hour |

| SJ-130 | SJ130/30 | 130mm | 33 | 450kg/hour |

| SJ-160 | SJ160/30 | 160mm | 33 | 600kg/hour |

| SJ-180 | SJ180/30 | 180mm | 33 | 750-800kg/hour |

Products Recommended

More +-

PVC braided hose extrusion line

This line is used to produce PVC fiber reinforced garden hoses with diameter from 8mm to 50mm. The hose wall is made of PVC material. In the middle of hose, there is fiber. According to request, it can make braided hose with different color, three layer braided hoses, five layer braided hoses.

The extruder adopts single screw with excellent plasticization; haul off machine has 2 claws with speed governed by ABB inverter; With proper the fiber layer could be crochet type and braided type.

The braided hose has the advantage of extrusion resistance, corrosion resistance, static electricity resistance, anti-high pressure and good running. It is suitable for the conveying high pressure or combustible gas and liquid, heavy suction and delivery of liquid sludge. It is mainly used in the garden and lawn irrigation.

Learn more -

PVC profile extrusion line

This line is widely used for producing various PVC profiles, such as PVC window&door profile, PVC ceiling panel, PVC trunking.

The process flow of this line is PVC powder + additive — mixing—material feeder—twin screw extruder— mould and calibrator—vacuum forming table—haul-off machine—cutting machine—discharge rack.

This PVC profile extrusion line adopt conic twin screw extruder, which is suitable for both PVC powder and PVC granules. It has degassing system to ensure the excellent material plasticization. The high speed mould is available, and it can largely increase the productivity.

Learn more -

PPR pipe machine

It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it can also produce mufti-layer PP-R pipes, PP-R glass fiber pipes, PE-RT and EVOH pipes. With years of experience for plastic pipe extrusion, we also developed high speed PP-R/PE pipe extrusion line, and the max production speed could be 35m/min (base on 20mm pipes).

Learn more -

PP pipe production line

It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it can also produce mufti-layer PP-R pipes, PP-R glass fiber pipes, PE-RT and EVOH pipes. With years of experience for plastic pipe extrusion, we also developed high speed PP-R/PE pipe extrusion line, and the max production speed could be 35m/min (base on 20mm pipes).

Learn more -

12-575mm6.5mm thick PE pipe production line

It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it can also produce mufti-layer PP-R pipes, PP-R glass fiber pipes, PE-RT and EVOH pipes. With years of experience for plastic pipe extrusion, we also developed high speed PP-R/PE pipe extrusion line, and the max production speed could be 35m/min (base on 20mm pipes).

Learn more -

Automatic pipe belling machine

1.this series can be processed Φ16-1000mm any pipe flaring

2.with automatic delivery tube.flip tube.flaring function

3.with heating.cooling.timing.automatic.manual function

4.the modular design of the components

5.small size.low noise

6.the use of vacuum adsorption.flaring a clear profile.size assurance

7.power (compared with similar products.power-saving 50%)

8.can be customized according to user requirements special specifications

Learn more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur