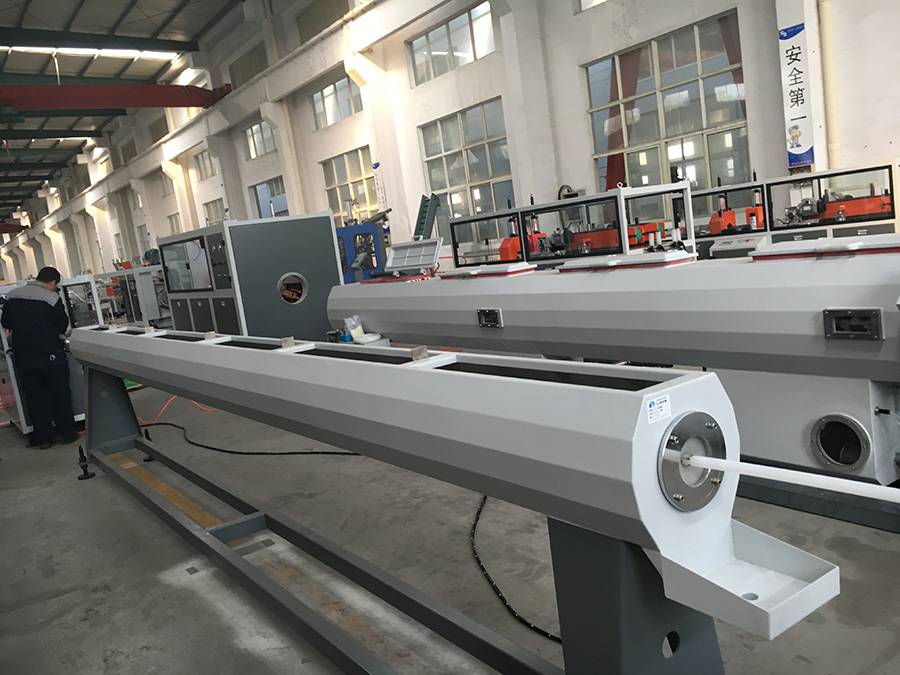

Single Wall Corrugated Pipe Machine - Manufacturers, Factory, Suppliers from China

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Single Wall Corrugated Pipe Machine, Plastic Ki Machine, Pet Bottle Baling Press Machine, Sabmann Blow Molding Machine,Pet Molding Machine. We hope to establish additional organization interactions with prospects all over the entire world. The product will supply to all over the world, such as Europe, America, Australia,Milan, Georgia,Zambia, Greece.In the increasingly competitive market, With sincere service high quality products and well-deserved reputation, we always offer customers support on products and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

Related Products