Special Design for Pani Bottle Packing Machine - PET bottle juice filling machine – FAYGO

Inquiry NowSpecial Design for Pani Bottle Packing Machine - PET bottle juice filling machine – FAYGO Detail:

Product introduction

This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce PET bottled juice and other non-gas beverage.

The CGF Wash-filling-capping 3-in-1unit:Beverage Machinery can finish all the process such as press bottle, filling and sealing.

It can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Technical parameter

|

model |

RCGF 14-12-4 |

RCGF 18-18-6 |

RCGF 24-24-8 |

RCGF 32-32-10 |

RCGF 50-50-15 |

RCGF 60-60-15 |

RCGF 70-70-18 |

|

suitable bottle size |

H:170-320mm Dia: 50-100mm volume: 330-2000ml Plastic bottle |

||||||

|

cleaning pressure(Mpa) |

0.25-0.3 |

||||||

|

capacity(b/h) |

2000 |

5000 |

7000 |

9000 |

18000 |

22000 |

25000 |

|

power(KW) |

2.2 |

3.5 |

3.8 |

5.5 |

10 |

13 |

15 |

|

dimension(mm) |

2100×1800 x2700 |

2600×2100 x2700 |

3200×2300 x2700 |

4200×2600 x2700 |

5700×3600 x2700 |

6000×4200 x2700 |

6500×4500 x2700 |

|

weight()KG |

2300 |

3500 |

4600 |

6500 |

10000 |

110000 |

130000 |

Main characters

1) To change bottle shape, the operator only needs to replace the star-wheel, inlet bottle screw and arc guide plate

2) The parts contacting media are made from stainless steel and have no process blind angles to enable easy cleaning

3) Stainless steel bottle clip, the clip does not touch the bottle screw, the rinsing nozzle is “plum blossom” shape, so it can care each inch of the bottle.

4) This machine adopts micro negative pressure hot filling, has high filling accuracy.

5) Screw capping machine designed according to Italy technical, France technology.

6) The cap feeder has the function of protection cap, and also can test no cap status and process cap adding.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Special Design for Pani Bottle Packing Machine - PET bottle juice filling machine – FAYGO , The product will supply to all over the world, such as: Denmark, Guatemala, Dominica, Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Products Recommended

More +-

Cheapest Factory Plastic Bottle Making Machine Price Supplierspet Bottle Moulding Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

professional factory for Double Wall Corrugated Pipe Machine - Automatic plastic pet bottle neck cutting machine – FAYGO

Product introduction Faygo automatic rotary cutting style is updating solution for this industry, it hugely reduces the cost for factory in labor, material and qualified rate. Our cutting adopts th...Learn more -

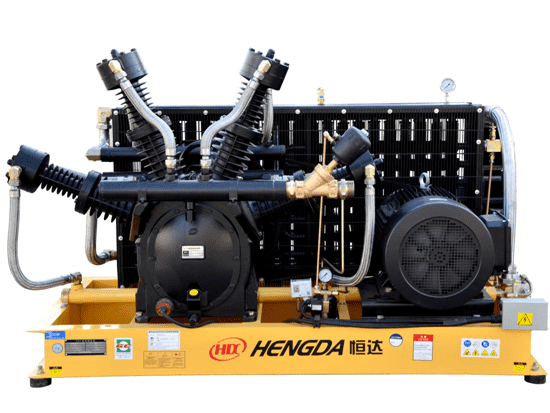

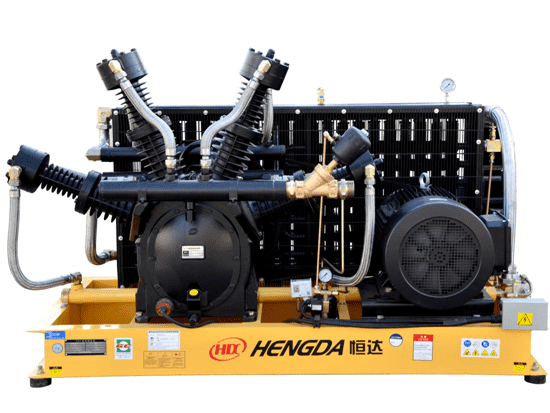

Massive Selection for Small Compressor Tank - Booster compressor – FAYGO

Learn more -

Discount Price Extrusion Machine For Sale - Single Screw Plastic Extruder Machine – FAYGO

HDPE pipe extrusion line It is mainly used for extruding thermoplastics, such as PE, PP, PS, PVC, ABS, PC, PET and other plastic material. With relevant downstream equipment (including moud), ...Learn more -

Hot Sale for 440p Compressor - Booster compressor – FAYGO

Learn more -

Reasonable price Small Air Compressor For Nail Gun - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more