Europe style for Toy Manufacturing Machine Price - Pet bottle crushing washing and drying line – FAYGO

Inquiry NowEurope style for Toy Manufacturing Machine Price - Pet bottle crushing washing and drying line – FAYGO Detail:

This Pet bottle crushing, washing and drying line transforms waste pet bottles into clean PET flakes. And the flakes can be further processed and re-utilized with high commercial value. The production capacity of our PET Bottle crushing and washing line can be 300kg/h to 3000kg/h. The main purpose of this pet recycling is to get the clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line. And also get clean PP/PE caps, labels from the bottles etc.

The PET bottle recycling line is consist of the following machines: de-baler, trammel, label remover ,manual sorting table, metal detector, crusher, pre-washer, hot washer, friction washer, float washing tank, dewaterer, drier, zigzag separator, storage hopper and electric control cabinet.

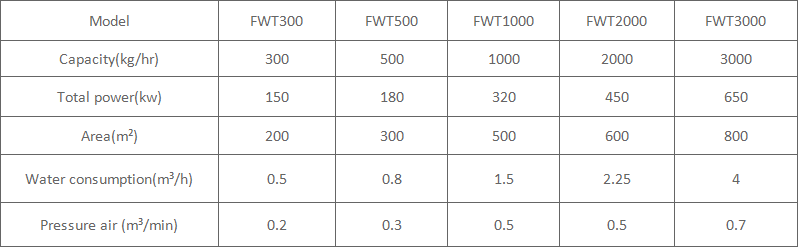

Technical data:

2.PP, PE Crushing, washing and drying line

This PP, PE Crushing, washing and drying line is mainly used to clean the waste plastics, such as PE HDPE LDPE LLDPE PP BOPP Film, bags, bottles, Jerry cans, bucket, basket etc. The waste dirty material will go through crushing, washing, drying, and collecting process, and turn to be clean flakes for pelletizing.

With high efficient crushing,washing and drying, the client can make clean plastic scraps from waste plastics with lowest cost.

The PP, PE recycling line mainly include crusher or shredder machine, friction washer machine, float washing tank, High speed friction washer machine, dewatering machine, hot air dryer system, storage silo etc.

The clean material machine from this washing line can be used to making plastic granules. Our company also supply plastic granulating machine for next process

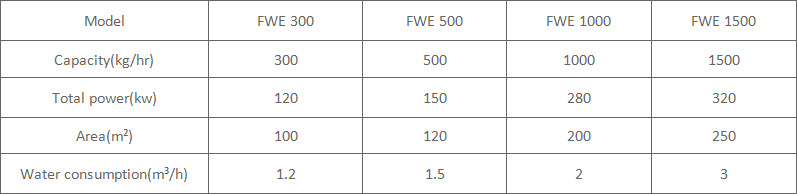

Technical data:

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Europe style for Toy Manufacturing Machine Price - Pet bottle crushing washing and drying line – FAYGO , The product will supply to all over the world, such as: America, Hungary, Iraq, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

Products Recommended

More +-

Factory Promotional Liquid Filling Bottle - Automatic carbonated beverage filling machine – FAYGO

carbonated beverage filling machine-Characteristics 1. This kind of carbonated beverage filling machine combines washing,filling and rotary capping functions in one unit.It is a fully automati...Learn more -

Factory supplied 12v Compressors 4×4 - SCREW COMPRESSSOR – FAYGO

Introduction Full-automatically load and unload control the input air full automatically. Compressor will start automatically when there is no pressure, and will stop working when the pressure...Learn more -

Leading Manufacturer for Pp Extrusion Machine - Automatic plastic pet bottle neck cutting machine – FAYGO

Product introduction Faygo automatic rotary cutting style is updating solution for this industry, it hugely reduces the cost for factory in labor, material and qualified rate. Our cutting adopts th...Learn more -

Super Lowest Price Pvc Water Pipe Extrusion Line - Single Wall Corrugated Pipe Making Machine – FAYGO

Detailed Product Description Application: Produce Single-wall Corrugated Pipes Rare Material: PP,PE,PA And PVC Granules Extruder Type: Single Screw Extruder Pipe Diameter: 4mm~100...Learn more -

Good Wholesale Vendors Tpe Sheet Production Line - Plastic Crusher Machine – FAYGO

Detailed Product Description Voltage: 380V, 3 Phase, 50Hz Weight: 1200kg Rotating Blades: 18pcs Company: Faygo Power(W): 18.5kw Dimension(L*W*H): 1500*1800*2000 Rotating Speed: 500rpm/m Model ...Learn more -

Competitive Price for Plastic Bottle Manufacturer Machine Price - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more