x

Best-Selling Jwell Extrusion Machinery - Automatic Winding Machine For Plastic Pipe Profile – FAYGO

Inquiry Now

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Granule Making Machine, Plastic Pipe Production Line, Pet Bottle Crushing & Washing Line, Our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

Best-Selling Jwell Extrusion Machinery - Automatic Winding Machine For Plastic Pipe Profile – FAYGO Detail:

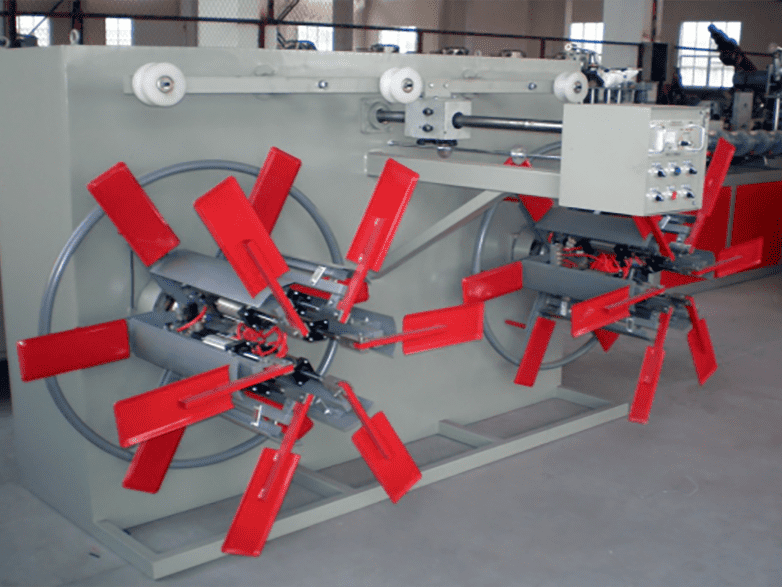

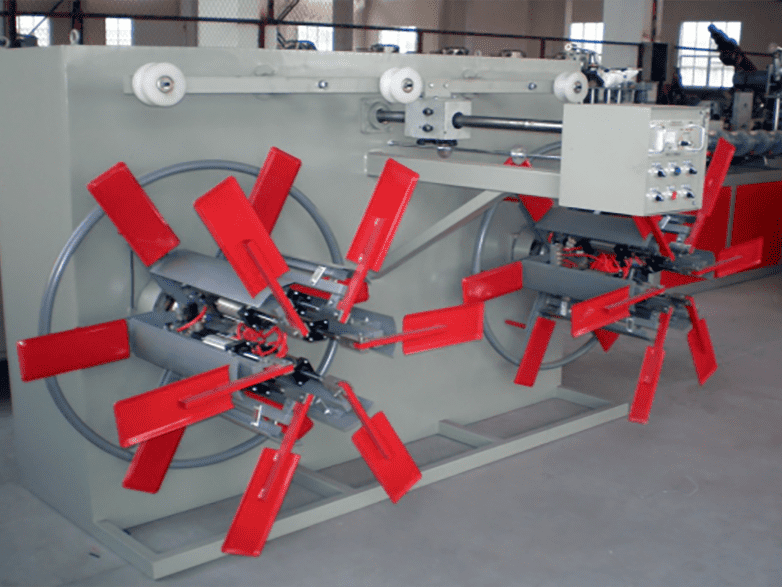

Automatic Winding Machine For Plastic Pipe Profile

Specification

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Best-Selling Jwell Extrusion Machinery - Automatic Winding Machine For Plastic Pipe Profile – FAYGO , The product will supply to all over the world, such as: Netherlands, Madrid, Bangladesh, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Best-Selling Jwell Extrusion Machinery - Automatic Winding Machine For Plastic Pipe Profile – FAYGO Detail:

Automatic Winding Machine For Plastic Pipe Profile

It is mainly used for winding PE pipe, alumium pipe, corrugated pipe, and other some pipe or profiles. This plastic tube coiler is highly automatic, and usually work with whole production line.

The plate is controlled by gas; winding adopt torque motor; with special equipment to arrange the pipe, this plastic tube coiler can wind pipe well, and work much stable.

The main model for this plastic tube coiler: 16-40mm single/double plate automatic plastic tube coiler, 16-63mm single/double plate automatic plastic tube coiler , 63-110mm single plate automatic plastic tube coiler.

Specification

| 1. | model: | SPS1200 | SPS1600 | SPS2200 |

| 2. | Winding diameter | 500-1000mm | 550-1500mm | 800-2000mm |

| 3. | Winding speed | 0.5-40m/min | 0.5-40m/min | 0.5-40m/min |

| 4. | Winding width | 300-500mm | 300-500mm | 300-500mm |

| 5. | Winding pipe diameter scope | Ø16-40mm | Ø16-63mm | Ø63-110mm |

| 6. | Air pressure | 0.6mpa | 0.6mpa | 0.6mpa |

| 7. | Torque motor | 10N.M | 10N.M, 25N.M | 25N.M x 2 |

| 8. | Dimension (mm) | 2800×1700×1800 | 3000×2800×2000 | 3000×3200×2000 |

| 9. | Weight | 1000kg | 1500kg | 2000kg |

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Best-Selling Jwell Extrusion Machinery - Automatic Winding Machine For Plastic Pipe Profile – FAYGO , The product will supply to all over the world, such as: Netherlands, Madrid, Bangladesh, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

By Amber from Karachi - 2017.08.16 13:39

By Amber from Karachi - 2017.08.16 13:39

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

By Dawn from Seattle - 2017.11.12 12:31

By Dawn from Seattle - 2017.11.12 12:31

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

Write your message here and send it to us

Products Recommended

More +-

Low price for Plastic Bottle Recycling - Automatic Winding Machine For Plastic Pipe Profile – FAYGO

Automatic Winding Machine For Plastic Pipe Profile It is mainly used for winding PE pipe, alumium pipe, corrugated pipe, and other some pipe or profiles. This plastic tube coiler is highly aut...Learn more -

Good Quality 7.5 Kw Screw Compressor - SCREW COMPRESSSOR – FAYGO

Introduction Full-automatically load and unload control the input air full automatically. Compressor will start automatically when there is no pressure, and will stop working when the pressure...Learn more -

Fixed Competitive Price 20 Liter Water Bottle Cap Making Machine Price - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

Factory directly Pprc Pipe Machine - PVC Pipe Production Line – FAYGO

Detailed Product Description model FGE63 FGE110 FGE-250 FGE315 FGE630 FGE800 pipe diameter 20-63mm 20-110mm 75-250mm 110-315mm 315-630mm 500-800mm extruder model SJ65 SJ75 SJ90 SJ90 SJ...Learn more -

Online Exporter Pet Bottle Compressing Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

OEM Supply Pe/Pp/Pvc Corrugated Pipe Production Line - PVC granulating line – FAYGO

HDPE pipe extrusion line This line is widely used to in PVC granules and CPVC granules production. With proper screw, it can produce soft PVC granules for PVC cable, PVC soft hose, rigid PVC g...Learn more