Melt-blown cloth develops faster among other cloth belonging to non-woven cloth, which is well-known as the one-step polymer process with the shortest flow in foreign countries.

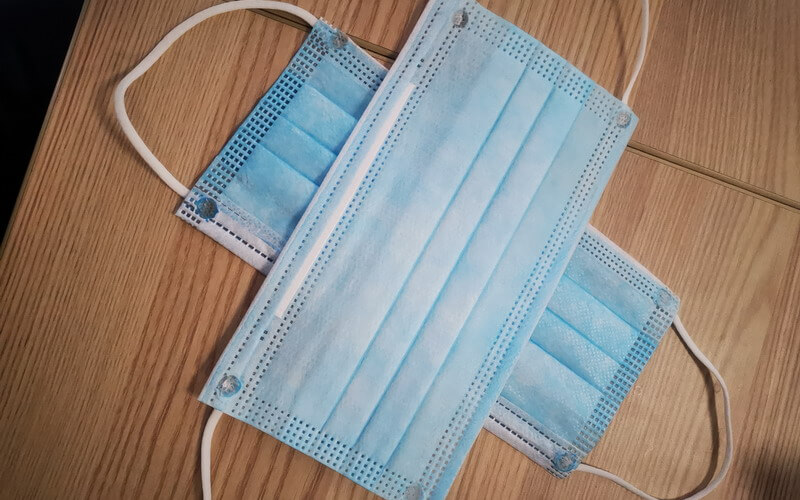

(mask with

melt-blown cloth)

Besides, it can also be made into medical materials, industrial precision wipes, thermal insulation material, oil absorption material, battery separator, limitation leather base fabric, etc. In many aspects, its performance is superior to that of traditional textiles. With the development of post-processing technology, the application of melt-blown cloth will be more extensive.

(melt-blown cloth

product line)

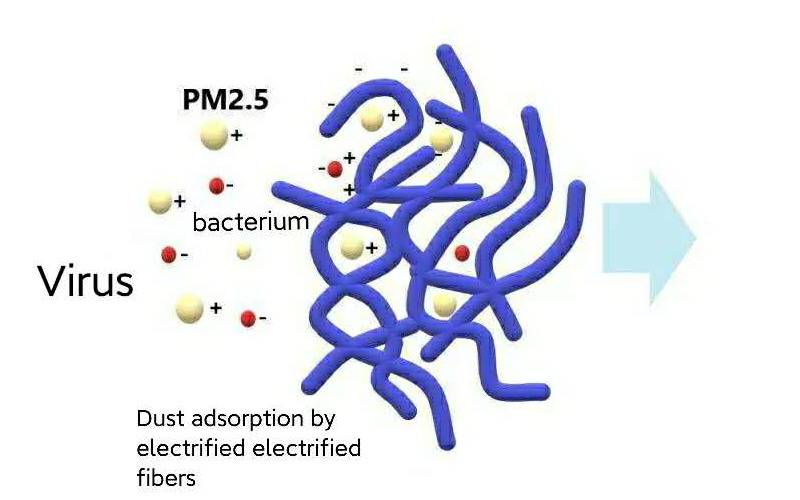

However, it is known to all, after a period of time, the filtering rate of the melt-blown cloth produced by most companies will decay out of a quite number of reasons, such as influence of temperature and humidity in the air as well as the loss of the electrons once the melt-blown cloth is produced, which is a common problem manufacturers facing.

On the contrary, what makes us proud is that, with years of research and modification, Jiangsu Faygo Union Machinery Co ltd provides customers with various melt-blown cloth product line, the quality and energy consumption of which are close to the advanced level of lar foreign machines.

Melt-blown cloth used on face mask produced by our machines reaches the international medical level, and the filtering level ranges from 95 plus to 99 plus.

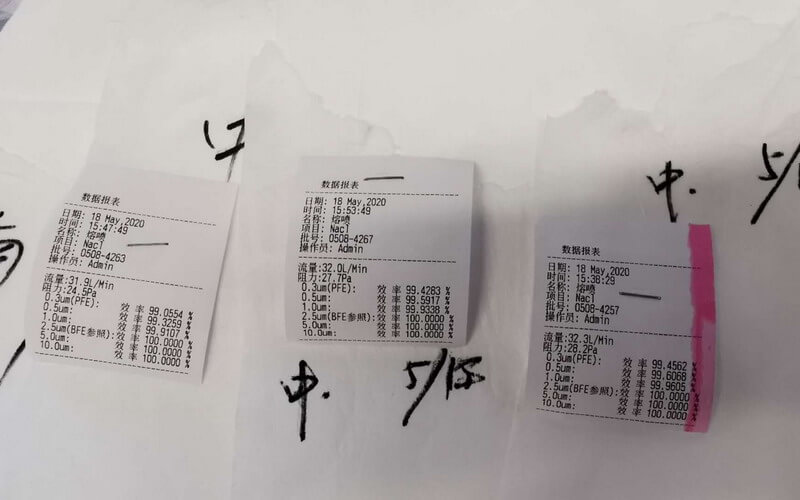

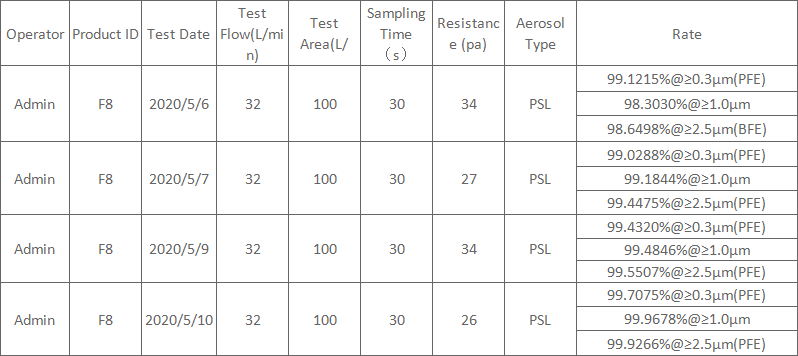

Since most companies have the difficulty in maintaining the filtering rate, we have carried out some tests on the melt-blown cloth produced by our machines in the past days.

Let’s take a look at some live date photos:

As can be seen from the live pictures and the data above, the filtering rate of the melt-blown cloth produced bu our machines, though reduced in the past days, still reaches the international medical level and its filtering rate ranges from 95 plus to 99 plus. For instance, the filtering rate of the cloth tested on 6th of May is around 99.12%. When it comes to 10th of May, the filtering rate of it is around 98.3030%. It turns out that Melt-blown cloth produced by Faygo Union Machinery Co ltd melt-brown stands the test of time.

For another word, qualified cloth is produced by an excellent machine. We have improved and adjusted our machines repeatedly not casually and will never settle. In a word, Faygo does not sell cloth, but sells machines that produce high-quality melt-blown cloth and our data speaks. Welcome to visit and investigate.